As the automotive industry evolves with rapid advancements in efficiency, safety, and sustainability, rubber and plastic components play an increasingly critical role in vehicle design and functionality. These materials not only reduce weight and cost but also enhance durability, sealing, and vibration control.

At DXTSEALS, we specialize in the custom manufacturing of rubber and plastic components for automotive applications, helping manufacturers meet high performance and quality standards.

🚗 Why Rubber and Plastic Are Essential in Automotive Manufacturing

Rubber and plastic are used extensively in vehicles due to their versatile physical and chemical properties. Their ability to resist wear, absorb shock, and withstand extreme conditions makes them ideal for a wide range of automotive parts.

Key Advantages:

-

Lightweight for better fuel efficiency

-

High resistance to corrosion and chemicals

-

Excellent insulation and sealing properties

-

Design flexibility for complex geometries

-

Cost-effective mass production

🛠 Common Rubber Components in Vehicles

-

Sealing Systems

-

Door seals, window seals, trunk seals

-

Engine gaskets and O-rings

-

Oil seals and shaft seals

-

-

Vibration and Noise Reduction

-

Engine mounts

-

Suspension bushings

-

Anti-vibration pads and dampers

-

-

Hoses and Tubing

-

Fuel lines

-

Coolant hoses

-

Air intake and vacuum tubes

-

DXTSEALS provides high-performance rubber compounds that meet automotive-grade requirements for temperature, pressure, and fluid resistance.

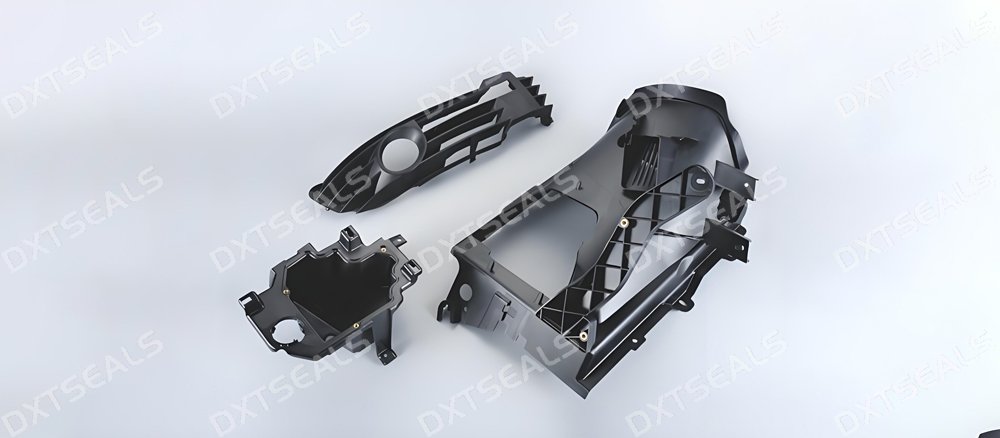

🔧 Plastic Components in Modern Vehicles

-

Interior and Exterior Trim

-

Dashboard panels

-

Door handles and switches

-

Bumper covers and grilles

-

-

Functional Engine Parts

-

Air filter housings

-

Valve covers

-

Cooling system components

-

-

Electrical and Safety Systems

-

Wire harness connectors

-

Sensor housings

-

Battery casings

-

Engineering plastics like PA, POM, ABS, PC, and PEEK offer outstanding performance for parts exposed to mechanical loads and thermal stress.

🌐 Customized Solutions by DXTSEALS

With years of experience in custom molding, CNC machining, and material formulation, DXTSEALS delivers tailored solutions for automotive manufacturers. We offer:

-

✔ Prototyping to mass production

-

✔ Automotive-grade rubber & plastic materials

-

✔ Tight tolerance machining for critical parts

-

✔ ISO-certified quality assurance

-

✔ Design & engineering support

Whether for electric vehicles, combustion engines, or hybrid systems, we help you enhance vehicle performance and reliability.

🔮 Future Outlook

As the automotive industry shifts toward electric and autonomous vehicles, the demand for lightweight, durable, and sustainable components continues to grow. Rubber and plastic will remain essential materials for innovation in next-generation vehicles.

🔚 Conclusion

From sealing and vibration control to structural and functional parts, rubber and plastic components are indispensable in modern vehicle design. At DXTSEALS, we provide custom-engineered solutions that support efficiency, safety, and performance in the automotive sector.

🔗 Learn more about our automotive rubber and plastic solutions at www.dxtseals.com

DXTSEALS – Empowering the Automotive Industry with Precision-Made Rubber and Plastic Components.