Related Products

Bearing Isolator Labyrinth Seal

Up to 3600 RPM (application-dependent)

-40℃ to +200℃ (-40℉ to +392℉)

Bronze, Stainless Steel, Composite, FDA Polymer

Horizontal and vertical

Bearing Isolator Labyrinth Seal – Non-Contact, Maintenance-Free Protection for Rotating Equipment

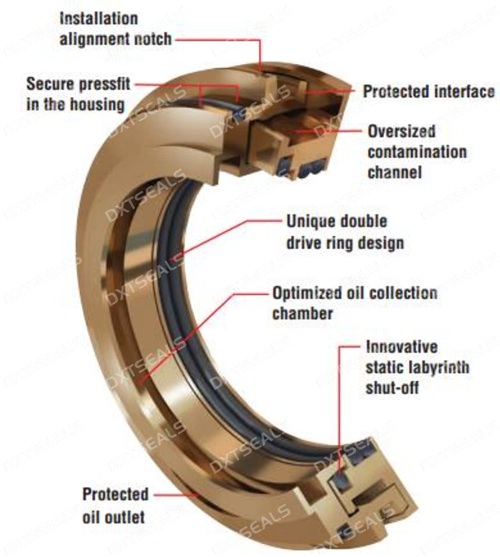

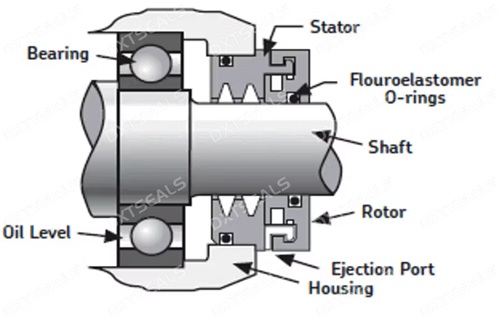

The Bearing Isolator Labyrinth Seal is a non-contact, dynamic sealing solution designed to protect bearing housings in rotating equipment from contamination and lubricant leakage. It utilizes a two-part design—rotor and stator—to form a complex labyrinth pathway that blocks ingress of dust, water, and other contaminants, while retaining lubrication within the bearing housing.

Unlike traditional lip seals, this labyrinth isolator operates without shaft contact, eliminating shaft wear, reducing friction, and extending equipment service life significantly. The seal is ideal for use in pumps, motors, gearboxes, fans, and other rotating machinery.

Non-Contact Design – No friction, no shaft wear

Contamination Exclusion – Labyrinth path blocks dirt, water, and dust

Lubricant Retention – Effectively seals in grease or oil

Maintenance-Free – Zero lubrication or adjustment required

Easy Installation – Press-fit or Cam-Lock designs available

High Performance Range – Handles extreme temperatures and environments

Versatile Applications – Suitable for pumps, motors, blowers, gearboxes

Electric motors and generators

Pumps and gearboxes

Blowers, fans, compressors

Industrial processing equipment

Power generation and mining machinery

Food and pharmaceutical machinery (FDA materials available)

Bronze

Stainless Steel

Aluminum Alloy

High-Performance Polymer (FDA grade optional)

Composite (metal + polymer)

Press-fit design

Cam-Lock design

Split-type isolators for large shafts

Horizontal or vertical mounting orientation

Single or dual sealing path options

| Parameter | Specification |

|---|---|

| Type | Non-contact Labyrinth Bearing Isolator |

| Structure | Rotor + Stator with multi-stage labyrinth path |

| Shaft Size Range | 0.5” to 12” (custom sizes up to 36”) |

| Operating Temperature | –40°C to +200°C (–40°F to +392°F) |

| Pressure Rating | Atmospheric (non-pressurized environments) |

| Rotational Speed | Up to 3,600 RPM (application-dependent) |

| Material Options | Bronze, Stainless Steel, Composite, FDA Polymer |

| Installation Methods | Press fit, Cam-Lock, or Split installation |

| Certifications (Optional) | IP66 / IP67 / IP69K / FDA / RoHS compliant |

| Lubricant Compatibility | Grease, mineral oils, synthetic oils |

| Application Orientation | Horizontal and vertical |

| Maintenance Requirements | None (zero maintenance, non-wearing) |

| Feature | Lip Seal | Bearing Isolator |

|---|---|---|

| Contact with Shaft | Yes (friction, wear) | No (non-contact) |

| Lifespan | 6–18 months | 5+ years |

| Contamination Barrier | Moderate | Excellent |

| Lubricant Retention | Fair | Excellent |

| Shaft Damage Risk | High | None |

| Maintenance | Periodic replacement | Maintenance-free |

Split design for retrofit installation

FDA-certified material for food & pharma equipment

High-speed balancing for applications >3600 RPM

Dust cover or rain shield attachments

Custom branding or laser engraving

Сообщение нам (click here to show/hidden)