As industries push for higher performance, longer service life, and extreme reliability, the demand for spring-energized seals (SES) continues to rise across sectors such as aerospace, chemical processing, energy, and medical devices. These high-performance seals require exceptional precision, making CNC machining not just useful, but critical to their manufacturing process.

At DXTSEALS, we combine decades of sealing expertise with cutting-edge CNC technologies to produce custom SES solutions that meet the most rigorous industrial challenges. This article explores the latest CNC innovations in spring-energized seal manufacturing and highlights key market trends driving demand.

🔧 What Are Spring-Energized Seals?

Spring-energized seals are high-performance components that combine a thermoplastic or elastomeric jacket with a metal spring energizer inside. This structure ensures:

-

Consistent sealing force under varying pressures

-

Low friction in dynamic applications

-

Excellent chemical and temperature resistance

Applications range from cryogenic systems to ultra-high-vacuum environments.

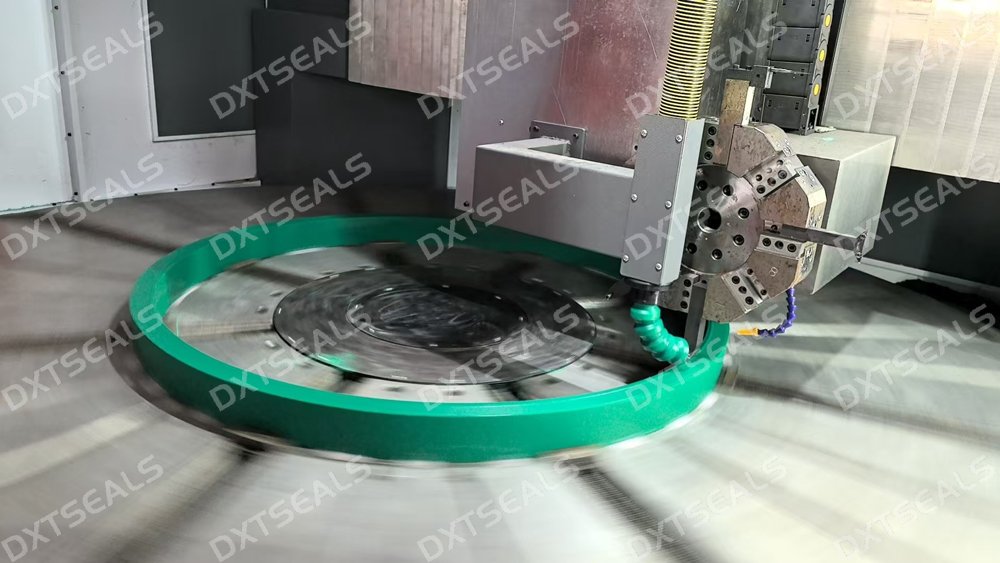

🛠 CNC Innovations in SES Manufacturing

1. Ultra-Precision Turning for Tight Tolerances

Modern CNC lathes with sub-micron resolution are used to machine seal jackets from PTFE, PEEK, UHMWPE, and other engineering plastics. Precision turning is essential for:

-

Consistent cross-sectional geometry

-

Zero-leakage sealing performance

-

Repeatability in high-volume runs

2. 5-Axis CNC Milling for Complex Profiles

As seal geometries evolve to meet new demands, multi-axis CNC milling enables:

-

Intricate grooves for spring retention

-

Asymmetric sealing lips for directional sealing

-

Integrated features that reduce assembly time

3. Micro-Machining for Miniature Seals

In medical and semiconductor fields, seals often measure just a few millimeters. CNC micro-machining tools allow DXTSEALS to manufacture miniaturized SES with flawless surface finishes and ultra-tight dimensional control.

4. Automated Toolpath Optimization

Advanced CAM software now uses AI-driven algorithms to optimize toolpaths for faster cycle times and improved tool longevity, minimizing production costs without compromising quality.

📈 Market Trends Shaping the Future of SES

✅ Trend 1: Growing Use in Electrification and EVs

Electric vehicles require non-conductive, high-temperature seals in battery and powertrain systems. CNC-machined SES made from filled PTFE or PEEK are ideal for these needs.

✅ Trend 2: Rising Demand for FDA-Compliant Materials

The medical and food sectors are driving the adoption of USP Class VI and FDA-grade SES. CNC precision is critical to ensure biocompatibility and zero particle generation.

✅ Trend 3: Customization Over Standardization

Off-the-shelf seals often can’t handle today’s demanding conditions. DXTSEALS offers full custom machining to meet unique operating pressures, temperatures, and chemical exposures.

✅ Trend 4: Smart Manufacturing Integration

CNC machines now connect to digital twins and smart factory systems, enabling real-time feedback and predictive maintenance—leading to consistent seal quality and reduced downtime.

🌍 Why DXTSEALS Leads in CNC-Driven SES Manufacturing

With our state-of-the-art CNC capabilities, DXTSEALS delivers:

-

🔹 High-precision sealing solutions tailored to extreme environments

-

🔹 Rapid prototyping and small batch production for R&D and new product development

-

🔹 Comprehensive material selection, including filled PTFE, PEEK, UHMWPE, and FKM

-

🔹 Strict quality control, with inspection using CMMs, optical measurement, and surface roughness testers

Whether you require vacuum seals for space missions or chemical-resistant seals for harsh industrial processes, DXTSEALS has the CNC and material expertise to support your success.

🧭 Conclusion: Precision Meets Innovation

The manufacturing of spring-energized seals has entered a new era, driven by innovations in CNC machining and changing demands from high-tech industries. By embracing these changes, DXTSEALS remains at the forefront—delivering custom-engineered seals that meet today’s toughest standards.

📞 Need a custom SES solution?

Visit www.dxtseals.com or contact our team to explore how CNC machining can enhance your sealing performance.