In high-performance sealing systems, temperature control is critical for ensuring reliability and extending service life. When seals operate in harsh conditions, the choice of metal support structures directly influences heat dissipation and thermal stability. Different metals exhibit varying levels of thermal conductivity, and this property can significantly impact sealing performance.

In this article, DXTSEALS compares the thermal conductivity of common metals and provides practical guidelines for selecting the right material for sealing applications.

1. Why Thermal Conductivity Matters in Sealing Systems

-

Prevents Overheating: Proper heat transfer helps maintain stable seal temperatures.

-

Enhances Material Longevity: Reduces thermal degradation of rubber and plastic sealing elements.

-

Improves Reliability: Minimizes seal hardening, cracking, or leakage due to excessive heat.

-

Supports Extreme Environments: Essential for high-speed rotating equipment, hydraulic systems, and engines.

2. Thermal Conductivity of Common Metals

| Metal | Thermal Conductivity (W/m·K) | Performance in Sealing Systems |

|---|---|---|

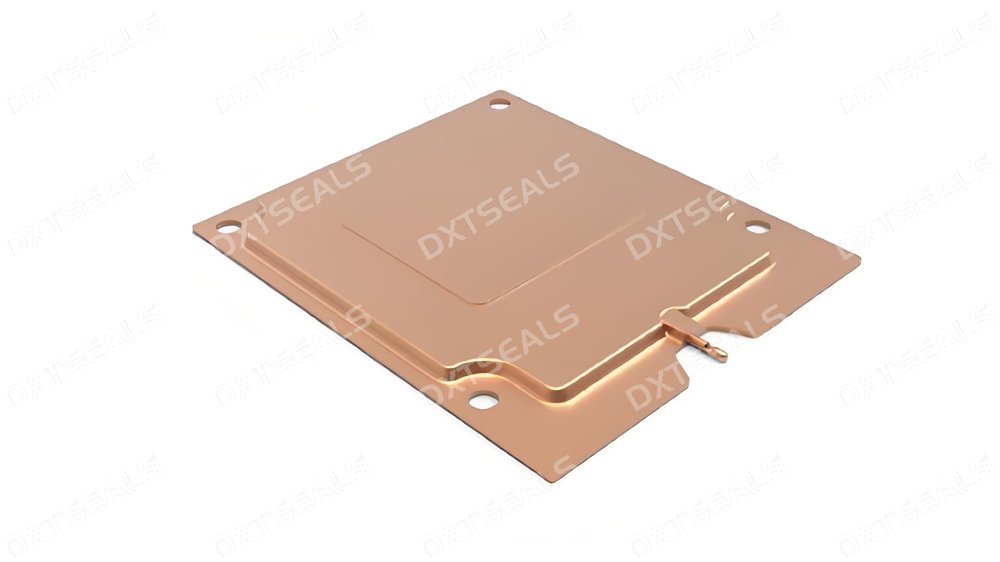

| Copper | ~390–400 | Excellent heat dissipation; suitable for high-heat applications |

| Aluminum | ~205–235 | Good balance of conductivity and lightweight properties |

| Brass/Bronze | ~100–120 | Moderate conductivity; corrosion-resistant support materials |

| Carbon Steel | ~50–60 | Lower conductivity; may retain heat longer |

| Stainless Steel | ~15–25 | Poor conductivity but strong corrosion resistance |

| Alloy Steel | ~30–50 | Balanced strength and moderate heat transfer |

3. Material Performance in Sealing Applications

-

Copper & Aluminum:

-

Excellent for heat-intensive applications, such as automotive engines or high-speed pumps.

-

Quickly dissipates heat, protecting rubber seals from thermal degradation.

-

-

Brass & Bronze:

-

Suitable for marine and corrosive environments where conductivity is less critical.

-

Often used in flange gaskets and sealing housings requiring durability.

-

-

Carbon & Alloy Steel:

-

Preferred for structural strength in high-pressure systems.

-

Conductivity is moderate; may require surface treatments or cooling design integration.

-

-

Stainless Steel:

-

Best for corrosive and hygienic applications (e.g., food, chemical, pharmaceutical industries).

-

Poor thermal conductivity means temperature rise must be carefully managed.

-

4. Guidelines for Material Selection

When choosing a metal for sealing support structures, consider:

-

Operating Temperature: High heat → copper/aluminum; moderate heat → steel/alloy steel.

-

Environment: Corrosive → stainless steel or bronze; general machinery → carbon steel.

-

Mechanical Stress: High load/pressure → alloy steel; lightweight applications → aluminum.

-

Cost vs Performance: Copper offers the best conductivity but comes at a higher cost.

5. Conclusion

The thermal conductivity of metals plays a vital role in sealing performance and temperature stability.

-

Copper and aluminum excel in heat transfer, protecting seals in high-temperature systems.

-

Stainless steel and carbon steel prioritize strength and corrosion resistance, but may require additional cooling considerations.

-

Brass, bronze, and alloy steels offer balanced performance depending on the working environment.

At DXTSEALS, we provide sealing support components in a wide range of metal materials, customized to meet your specific operating conditions. Our expertise ensures that your sealing system achieves optimal thermal performance, durability, and reliability.

📩 Contact DXTSEALS today to get expert advice on metal selection for sealing applications.